PlantStar BLOG

Benefits of Digital Transformation (DX) for Manufacturing

Dec 18, 2019 1:17:30 PM / by David Crowley

Where is your company on the roadmap toward sustainable relevance in the manufacturing space? Are you prepared to pursue digital transformation (DX) strategies in your manufacturing environment? Identifying opportunities to adapt to a new method is the key to keeping up in a competitive marketplace with technology at the forefront.

Defining Digital Transformation

In short, digital transformation is a shift in business processes driven by changes in customer demand. At its most elemental, DX means thinking critically about how your business does what it does, and how you can do it better through implementation of technology. This use of increasingly innovative technology will help evolve the production landscape and drive a push toward enhanced efficiency for manufacturers.

Digital Transformation Deconstructed

Think about how your customer base has changed over the last five years and the last 15 years. What's different? Do your long-term customers still want the same thing, in the same way, and according to the same specs that they came to you with at the beginning of their relationship with your business? Probably not.

The landscape has shifted. The fourth industrial revolution is upon us, and while its impact is still unfolding, one thing is clear: any manufacturing company's ability to survive and thrive will be determined by the degree to which that company manages to achieve agility in manufacturing processes. Current customers expect faster turnaround times, higher quality products, and greater customization, all of which place a burden on manufacturers to be able to deliver and stay competitive and relevant in their space. If you're not meeting and exceeding customers' expectations, it's time to rethink your business model.

Implementing a DX Strategy

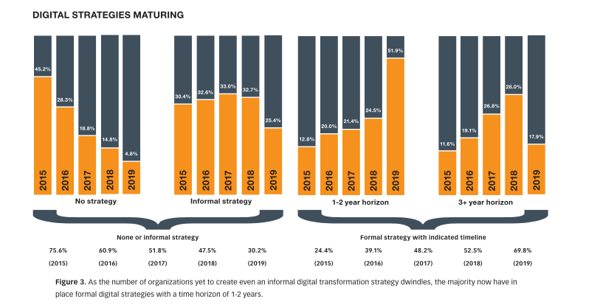

According to Smart Industry's 2019 State of the Initiative Report on DX, fewer than 5% of global manufacturers have yet to begin considering a DX strategy for their operations. If you're part of this 4.8%, you have a great opportunity to look towards improved efficiency.

When planning for your company’s future, ask yourself several questions:

- Do you know what potential and existing customers expect of your company and how you can provide that?

- Where are your shortcomings?

- Which processes or projects trip you up?

- What's keeping you from landing new business or delighting your long-term customers?

You probably have a sense of the pain points on your shop floor (machines that consistently break down, employees who make frequent mistakes, processes that never seem to improve), but understanding the answers to these questions will allow you determine where technology can play a role in helping fix any flaws in your current processes that might prevent you from consistently meeting customers’ expectations.

How you integrate technology with the people, processes, machines, and materials you're already using is up to you—but in order to take a strategic approach, you need accurate data. The more data you have, and the more that data is generated automatically instead of being gathered and copied manually, the more prepared you can be to make changes that improve your company's future. Capacity for both data capture and analysis will continue to separate one manufacturer from another in the global race to provide the best product to the widest market in the shortest time possible.

Clearly communicating your DX plans to anyone in your organization who will be affected is crucial. Even for the biggest corporations that pour billions of dollars into DX strategies, lack of communication with everyone involved is a recipe for failure. Remember, your people are your most valuable assets.

Finding the Right Technology Solution

When you’re ready to take the next step and introduce more technology into your operations, be sure to identify the right systems for your specific needs. Effective manufacturing execution system solutions give you the data you need, at scale, to make decisions that affect and ensure your future. Don’t overlook the benefits they can provide in terms of simplifying your processes and setting your company on the path towards automated success.

For more updates about transformations in the manufacturing industry and ways to improve your operational efficiency and gain a competitive advantage, subscribe to our blog!

Subscribe to Email Updates

Posts by Topic

- Manufacturing Execution Systems (38)

- manufacturing solutions (16)

- MES 101 (13)

- Industry 4.0 (11)

- improve efficiency (10)

- Plastic Molding (9)

- Plastics Technology (9)

- mes software (9)

- mes solutions (9)

- MES hardware (8)

- Shop Floor Production (8)

- digital transformation (7)

- Reduce scrap (6)

- data-driven-decisions (6)

- Medical molding (5)

- lean manufacturing (5)

- process monitoring (5)

- product quality (5)

- lights-out manufacturing (4)

- manufacturing dashboard (4)

- production monitoring (4)

- ERP integration (3)

- Shop Floor Safety (3)

- supply chain management (3)

- Injection Molding Technology (2)

- defect collection (2)

- machine mes (2)

- process variables (2)

- digital strategy (1)

- labor gap (1)

- throughput (1)