Manufacturing Execution Systems (MES) 101

Labor shortages, technological advances, and an increasingly competitive environment are causing manufacturers to update their operations with technology that lets them do more with less. A manufacturing execution system (MES) fills this need by providing clear, organized, real-time visibility into production and process data, creating new opportunities to increase efficiency, cut waste, and boost both product quality and profitability.

MES software has become the backbone of many manufacturing operations. However, manufacturers who have not yet adopted this technology often need a primer to fully understand what an MES does and how it can impact the way they do business. So, here it is! Welcome to MES 101.

What is an MES?

A manufacturing execution system runs on innovative, interactive software that connects, monitors, and manages manufacturing operations on the shop floor. It captures what’s happening in real time, such as whether machines are running or idle, how many parts are being produced, reject rates, process parameters, and worker activity, and displays this information in easy-to-read reports and dashboards that enable timely, data-driven decision-making.

The MES replaces time-consuming and error-prone manual data entry and paper records, ensuring that data flows continuously from machines and operators into the system. That data then feeds dashboards, reports, and alerts to provide an accurate, up-to-date picture of production performance, overall equipment effectiveness (OEE), product quality, labor activity, and throughput across the plant.

Because MES software is highly configurable, it is relevant across segments of the manufacturing industry. So, whether your plant is manufacturing medical devices, plastics, automotive, food and beverage or something entirely different, an MES can help users see how to optimize operations and track how improvements impact profitability, efficiency, and more.

How does an MES work?

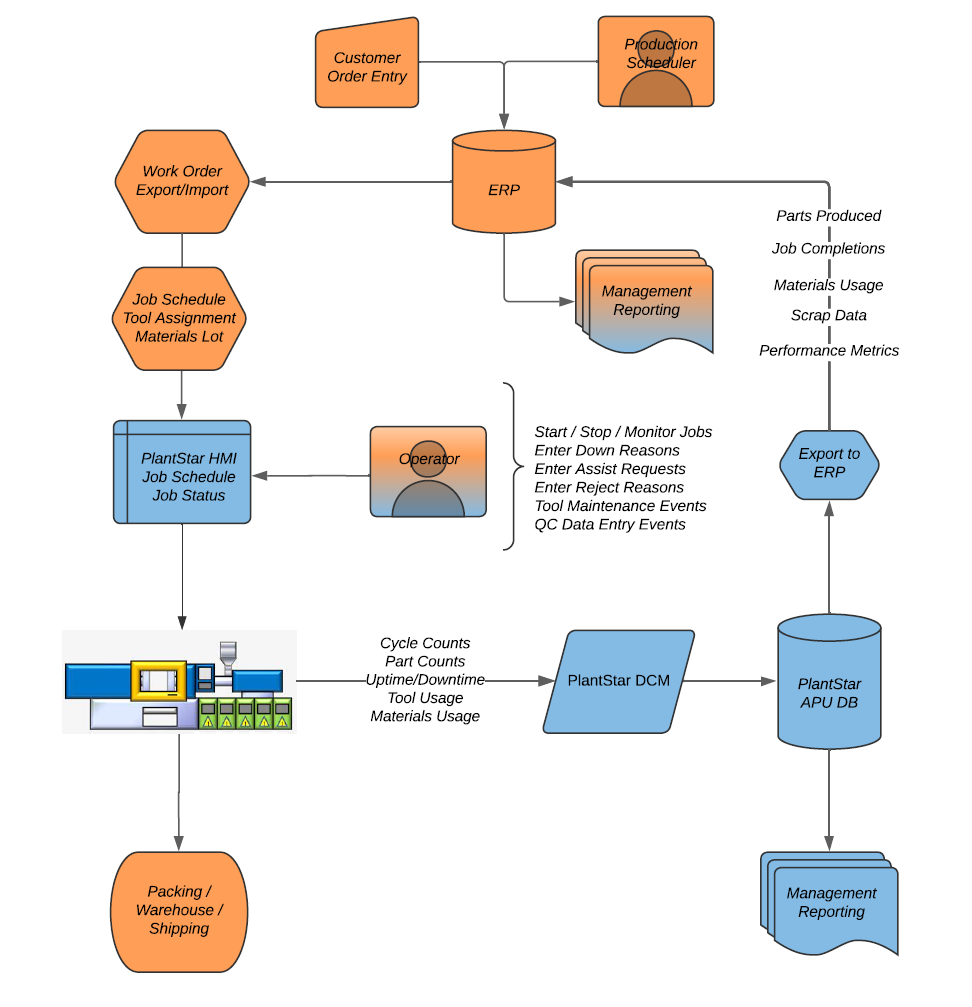

An MES compiles data from various components of your plant, such as machines, sensors, and operators, into a centralized data analysis system. This data is then displayed in configurable reports and dashboards. To provide end-to-end visibility into production and processes, a complete MES includes the following components:

The MES is powered by the application processing unit (APU)—a server that comprises both a central processing unit (CPU) and a graphics processing unit (GPU). The APU both houses and analyzes the data collected. (Cloud-based MES services are also available.)

The Data collection module (DCM) connects to machines, gathers data, and relays it to the APU.

The MES connects to machines and other manufacturing equipment utilizing machine protocols such as OPC UA, Modbus, Euromap, etc. There is no additional MES hardware needed when utilizing machine interface protocols.

The human-machine interface (HMI) displays data from the MES in organized reports. It also allows operators to interact with the system and enter information such as downtime, rejects, or job edits. The HMI could be an industrial touch screen device, tablet, or PC.

Manufacturers can optimize their results by ensuring the MES works seamlessly with their enterprise resource planning (ERP) and material resource planning (MRP) systems. In an integrated system, the MES creates a bridge between planning systems and what’s happening in real time, enabling just-in-time production and efficient, agile maneuvering of demand fluctuations. Shop-floor data can then flow back to the planning systems to improve forecasting, planning, and procurement by grounding high level decisions in real-world experience.

Overall Equipment Efficiency is how manufacturers measure the effectiveness of manufacturing processes. This takes into account the availability of the machines, the performance (or speed) of the machines, and the quality of the parts. With an MES, manufacturers are able to gain insights into their processes to maximize OEE.

Production & Process Monitoring

An MES can perform two distinct kinds of monitoring: production monitoring and process monitoring. Production monitoring focuses on how many parts are produced and rejected over a specified period of time and allows operators to track the progress and performance of each job.

Process monitoring, on the other hand, uses data from machines to capture process variables like cycle time, temperature, pressure, machine status, and more to enable statistical process control. When measurements show performance outside set parameters, instant notifications can alert decision-makers, who can then act quickly to minimize waste and downtime and protect worker safety.

Core Functions of MES

The widely accepted standard for MES functionality comes from the MESA-11 model from MESA International. The model includes twelve core functions:

This functionality enables finite-capacity scheduling: considering all constraints (e.g., machines, labor, materials, tooling) to generate realistic, achievable production plans. This allows manufacturers to calculate more accurate lead times, optimize sequencing, plan changeovers, and schedule predictive maintenance.

Tracking and management of resources in real time helps ensure the right equipment, materials, and people are available and ready when needed to meet production and scheduling goals. This helps prevent bottlenecks and under- or over-allocation of resources.

This function directs the flow of jobs, batches, or orders from planning systems into production on the shop floor in alignment with production schedules. It allows for real-time changes like rework, recovery, or salvage and management of work-in-progress (WIP) buffers. It also maintains records of work performed, customer communications, and notes, and can track customer profitability.

Dispatching automatically assigns the right resources to the right job by matching skill sets, territories, customer requirements and resource costs, enabling manufacturers to cut costs by up to 25%.

Document integration functionality manages and distributes relevant documents such as work instructions, process specs, design drawings, certifications, and safety/ISO compliance documents. Part images, videos, csv, pdf, etc., can be uploaded into the MES system to give operators easy ongoing access to correct, up-to-date procedures.

Tracking includes the full history of every unit, batch, or lot—from raw materials through production and packaging. This feature maintains records of which machine, operator, and materials were used, at what times, and under what conditions, enabling traceability, recall capability, and compliance. Especially for manufacturers in regulated industries, comprehensive tracking is key for risk mitigation and consumer protection.

Performance analysis compares live and historical performance data—such as machine utilization, cycle times, throughput, scrap, downtime, and schedule conformance—to targets or benchmarks. This provides decision-makers with insight into key performance indicators (KPIs) like OEE, resource utilization, production cost, lead time, and many more.

Labor management functionality tracks and manages operator assignments, skills, and authorizations. It monitors labor time by activity, such as direct production time, tool-room activity, material prep, and indirect tasks. This insight enables better labor allocation, shift planning, and activity-based costing.

Maintenance management includes planning, scheduling, and logging maintenance and tool/machine usage. The MES tracks machine cycles, tool life, and timing of maintenance activities, enabling predictive or preventive maintenance programs that increase efficiency, prolong machine life, and minimize downtime.

Process management monitors process data like machine states, operating parameters, changeovers, transitions, and inter-machine flows. It can then make automatic corrections or provide necessary details to guide corrective actions from operators to improve in-process activities.

The MES captures and analyzes critical process and product quality data (e.g., temperatures, pressures, cycle parameters), and compares them to engineering specifications. This functionality provides a basis for statistical process/quality control (SPC/SQC), rejecting defective parts and triggering alerts or shutdowns if parameters are violated to maintain consistent product quality and compliance. It also supports offline inspection operations and maintenance of laboratory information management systems (LIMS).

An MES allows for the creation of QC data entry events associated with production job data. As samples are inspected, the resulting data is recorded, time-stamped, and associated with production jobs or part numbers. This allows quality control data entry events to be recalled and reviewed for historical jobs and custom QC data entry forms to be created that display QC event data according to customer requirements.

The MES collects data from machines, sensors, lab systems, or operators in real time. This data is then used in analytics and displayed in reports and dashboards. The data is also used for purposes like ensuring traceability, verifying maintenance logs, and maintaining quality control records.

A complete MES should include all twelve of these functionalities. While each delivers value on its own, together, they create a powerful, unified system for managing and optimizing manufacturing operations.

What do you gain with an MES?

-

1

Prominently placed dashboards provide real-time visibility into everything that’s happening on the floor. Managers no longer have to wait for shift reports or batch logs to see how a production run went.

-

2

With maintenance scheduling, tool usage tracking, and instant alerts when machine or process issues arise, manufacturers reduce downtime, increase productivity and OEE, and extend equipment life.

-

3

Continuous monitoring of process parameters and quality data improves product quality and consistency, while instant alerts, rejects, or shutdowns enable reductions in scrap, waste, rework, and compliance risk.

-

4

Labor management and resource allocation ensure the right people and tools are used for each task, enhancing efficiency and maximizing throughput.

-

5

Product tracking, genealogy, document control, and record keeping create a reliable history for every product or batch for full traceability and compliance.

-

6

Performance analysis and reporting provide actionable metrics for data-driven decision-making, helping managers identify bottlenecks, optimize processes, and make continuous improvements.

-

7

Eliminating manual data entry reduces errors, delays, and administrative burden, freeing employees to focus on tasks that enhance productivity and profitability.

The PlantStar MES

PlantStar is an MES that’s trusted by more than 300 manufacturers on three continents. Our customers report a 30% efficiency gain with PlantStar, and our expert support team ensures smooth implementations, integrations with existing systems, and updates. Once you’re up and running, we provide robust support and remote management to keep your system working smoothly. As your business evolves, our team is here to advise you on adapting your system to meet new goals or requirements.

PlantStar’s dashboards and alerts are highly configurable to ensure key employees get the information they need when they need it. Our solution also supports deep integration, pulling data from the ERP and feeding it data from the shop floor. The result is end-to-end visibility and unprecedented control over productivity, efficiency, safety, and profitability.