Cutting-Edge Manufacturing Execution Systems

Launch your company into the digital age with simple solutions to monitor manufacturing and process data in real time.

Simplifying Manufacturing Processes

Are you tired of unexpected downtime within your plant? What about supply chain issues or labor shortages? Are you still collecting manual data? The PlantStar 4.0 Manufacturing Execution System (MES) software provides production and process monitoring capabilities, making manufacturing headaches a thing of the past.

PlantStar Features

- Job Scheduler

- Job Summary

- Job Shift Summary

- OEE Dashboard

- Production Summary

- Production Events

- Reject/Scrap

- Downtime

- Email, text and voice alerts

- Production Dashboard

- Machine Interface Support

- End of shift reporting

- Operator Action Security

- Tool Life Tracking

- Labor Tracking

- Label Printing

- ERP Interface/Integration

- Material Usage, Forecasting and Lot Tracking

- Process Monitoring

- Process Variable Overlay

- Weigh Scale Integration

- Vision System Integration

- Bar Code scanning

- Custom Reporting

Production Monitoring

Production Monitoring is our standard system that focuses on part counting, reject counting, email/text alerting, tracking uptime/downtime, oee tracking, standard and custom reporting and much more. With over 50 years of experience we have the ability to connect to any machine and other equipment.

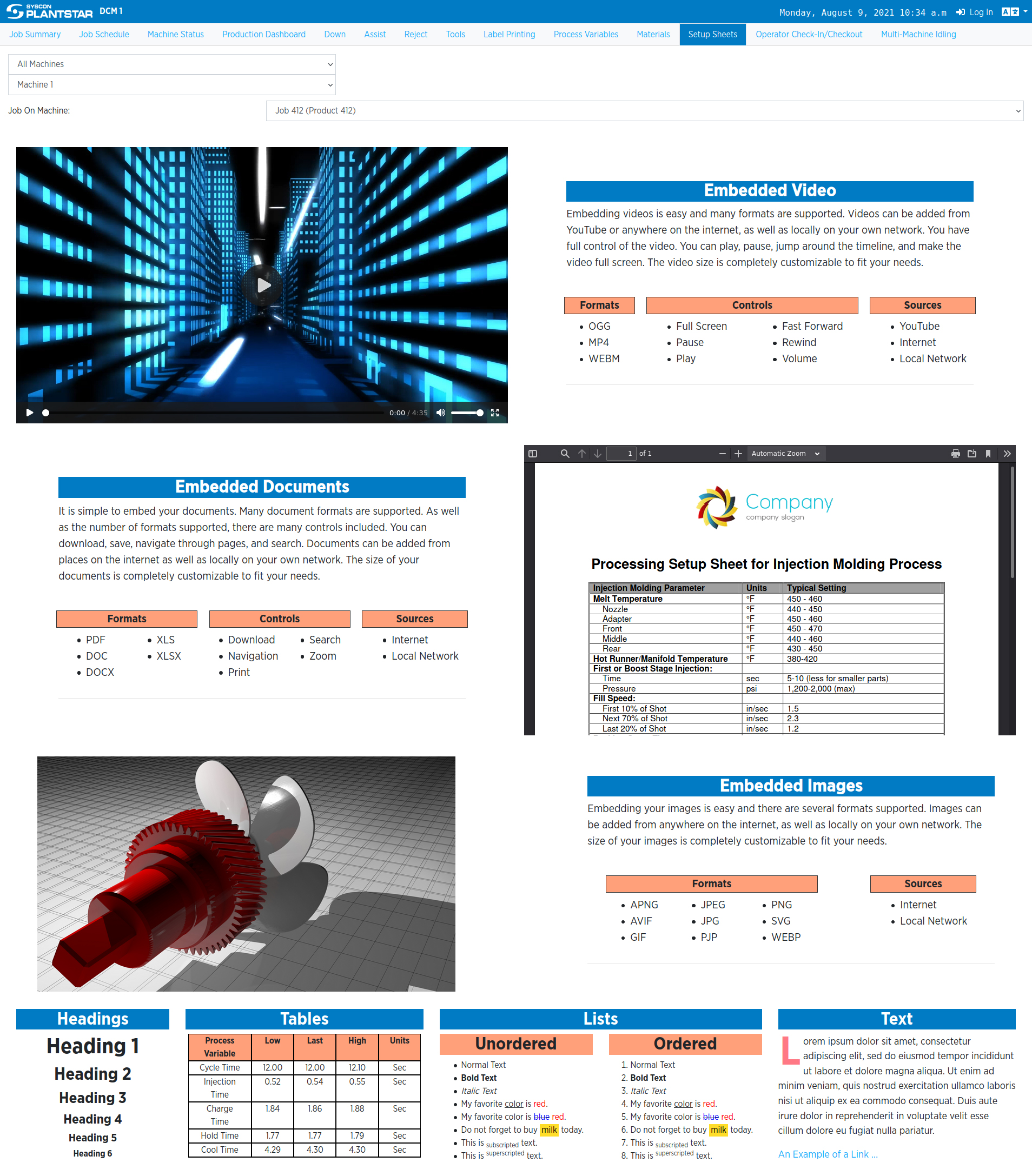

Process Monitoring including Process Overlay

The PlantStar system has the ability to measure process variables and provide SPC analysis. With our extensive background we have the ability to utilize machine interface types like; Euromap, OPC-UA, ModBus, V50/V70 etc. We also can monitor through an analog interface.

Collect Process Data for;

- Time between signals

- Temperature

- Pressure

- Position

- Profiles, readings per cycle, X Bar-R

- Process Overlays

Process Variables monitored are based on the customers wants and needs. Some common process variables we monitor are; Inject time, pack time, cure time, blow delay time, blow time, transfer time, screw forward, screw rotate, barrel, nozzle and manifold heat zones, mold water zones, and much more. The customer has the ability to set their limits and the PlantStar system can trigger alerts, alarms etc. based on these pre-determined limits.

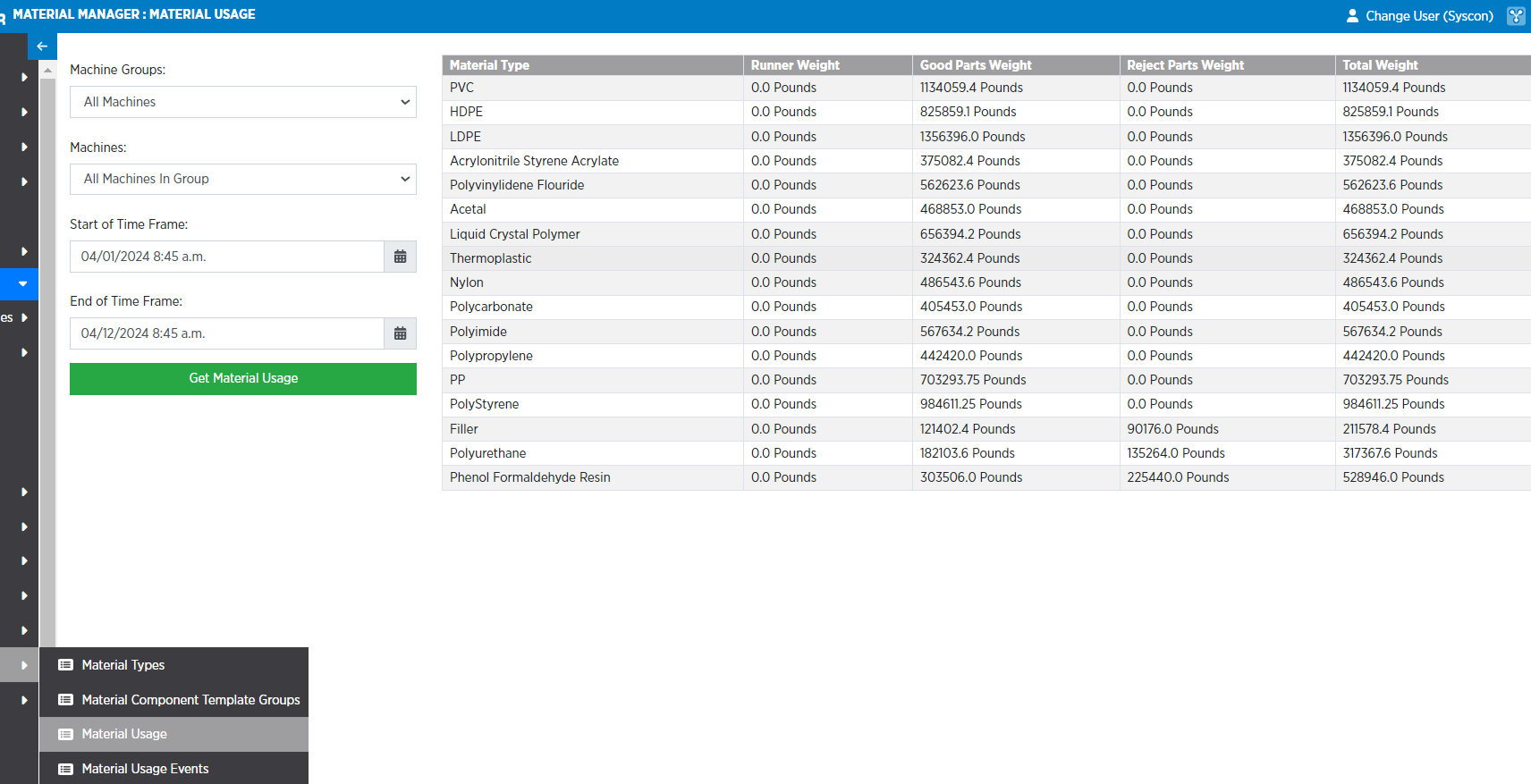

Material Lot Tracking

Track material lot numbers from ERP work order through production and maintain association between material lots and jobs, work orders, and finished goods to provide traceability and control.

Material Usage Reporting

Generate reports on materials by job, shift, day or other period. Export data back to ERP to improve operations.

Generate reports on materials by job, shift, day or other period. Export data back to ERP to improve operations.Material Forecasting

Anticipate material usage/demand based on scheduled jobs and materials specifications. Combine material specifications with job scheduling information to forecast material requirements based on schedule. Provides material forecast report and includes calendar of material changeover events.

Tool Life Tracking

![]()

Tracks the time used and number of cycles that an individual tool was used. Required to access the Tool Maintenance; where information is entered for maintenance performed on the tool.

End of shift reporting

Create custom end of shift reports which can be automatically emailed to certain users at the end of every shift or multiple times per day. Some examples are OEE by shift, production reporting, Material usage, reject and down reporting.![]()

Operator Action Events

Auto-generated data for each time an operator logs in or out into the system. Auto displays all operators on when they checked into a machine/station and where they are checked in on the shop floor.

Label Printing

Label printers may be connected via network or directly to a PlantStar DCM and barcode or other labels may be printed for any process requirement.

Label printers may be connected via network or directly to a PlantStar DCM and barcode or other labels may be printed for any process requirement.

ERP Interface

Customized interface for import/export of production schedules and related information from ERP systems. We integrate with all ERP/MRP systems.

Text to Voice Paging

PlantStar has the ability to broadcast messages related to currently monitored exception conditions. Examples of machine status are; Down, Idle, Fast, Slow, production and prrocess variable exceptions.

Net Parts Counting

This feature allows PlantStar to receive information on good parts that are confirmed as finished goods. A signal is used each time you complete a carton or pallet and PlantStar logs the number of units. We provide push button, sensors and can also interface with printers, scanners, vision systems and weigh scales.

OEE Tracking and Reporting

.jpg?width=6092&height=3767&name=Samsung%2043%E2%80%9D-85%E2%80%9D%20TVs.3-pop%20up%20(1).jpg) Real-time OEE dashboard that is viewable on any device. Dial down Availabiliy, Performance and Quality. Immediate results for Part efficiency, how a machine is running on available time and how you are running against your standard. End of shift and auto generated reporting available to track OEE.

Real-time OEE dashboard that is viewable on any device. Dial down Availabiliy, Performance and Quality. Immediate results for Part efficiency, how a machine is running on available time and how you are running against your standard. End of shift and auto generated reporting available to track OEE.

Job Setup Sheets

Industries We Serve

Mid- to large-size companies with separate manufacturing processes will benefit from PlantStar’s Manufacturing Execution System. Our comprehensive MES solutions improve manufacturers’ profitability in a variety of industries.

Typical applications for MES solutions include:

Plastics & Rubber

Retail Equipment & Tools

Fasteners

Chemicals

Medical

Construction

Life Sciences

Paper & Printing

Aerospace

Textiles & Clothing

Automotive

Oil & Gas

Consumer Electronics

Cable & Wire

Customers Using PlantStar

.png)

Our Additional Solutions

Hardware

PlantStar’s hardware solutions ensure your company’s manufacturing processes run smoothly. Our hardware, paired with our reliable manufacturing systems, prevents downtime and helps keep your plant running smoothly.

Explore Hardware

Support Services

Are you struggling to get your machines running after unexpected downtime or need help installing equipment? We’re here to provide support and help you keep your business running smoothly.

View Support Services

About Us

For more than four decades, we’ve help our customers find effective MES solutions that simplify their manufacturing processes. At PlantStar, we are dedicated driving results and building lasting relationship with our customers.

Learn More About Us

Real-Time Data

Real Results

0%

of global manufacturers use real-time reporting to improve productivity

0+

global implementations in the U.S., Canada, Mexico, Europe and China

0%

of our customers have utilized PlantStar for 20+ years

0%

increase in customer efficiency using PlantStar software

PlantStar Blog

Contact Us

Get in touch with us today to schedule a demo or learn more about how PlantStar can help your plant!