Real-Time Insights for Smarter Manufacturing

In manufacturing environments, process parameters like machine temperature, pressure, speed, and time impact outcomes in a variety of ways. Process variables can influence productivity, product quality, batch consistency, and more. When a critical process variable drifts out of spec, it can cause defects, waste, product recalls, and even safety hazards. If a forming press begins running slightly hotter than spec or a mixing process runs too fast or too long, it could impact product quality in ways that aren’t immediately obvious, leading to waste and dissatisfied customers.

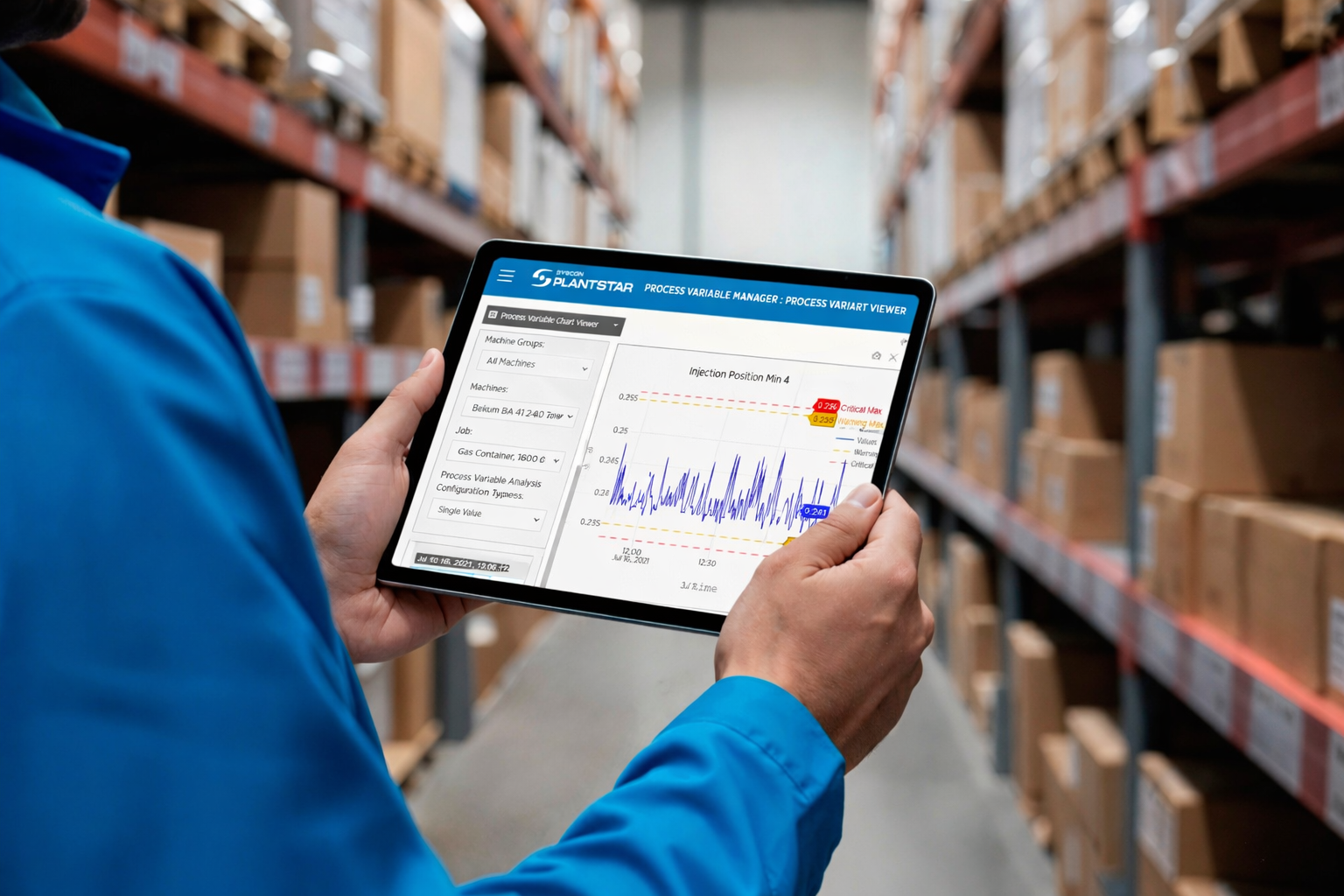

Process monitoring enables you to measure and track each machine’s operation in real time and automatically alert staff when parameters are exceeded. This way, you can catch problems earlier, create more consistent products, and support continuous process improvement. It also logs historical data to spot and analyze trends, track variations, and identify recurring issues early—before they become costly.

Unlike production monitoring, which focuses on productivity and efficiency (how many things are produced in a given period of time), the focus of process monitoring is on how the products are made. Process monitoring is commonly used to ensure product quality, which is particularly critical for products that must meet regulatory compliance, and to inform predictive maintenance planning, which helps extend equipment life, reduce unplanned downtime, and let you get more out of your maintenance budget.

Process Monitoring with PlantStar

PlantStar captures a wide range of process data in real time for a continuous picture of machine operation.

- Thermal variables such as oil temperature, heat zones, and water cooling zones

- Cycle variables like blow, blow delay, pack, cure, transfer, and screw times

- Machine variables like clamp force and pressure during specific process points

When variables stray from the parameters you set, configurable alerts automatically notify key employees of the issue. If you choose, certain events can even trigger machine shut-off. Instant alerts and triggers like these help you save time, money, and materials while maintaining a safer workplace.

PlantStar also lets you save process profiles that contain target values and acceptable tolerances for defined variables when producing specific parts or jobs. Then, each time you run a job, the system can automatically reference the corresponding profile, record real-time data, and compare actual performance with your standards.

Connect PlantStar to Your Equipment

PlantStar supports multiple ways to connect to and collect data from your machines and sensors.

- Industrial communication protocols like OPC-UA, EUROMAP, or MODBUS for modern, networked machines

- Analog input for sensors that output an analog signal, such as thermocouples or transducers

- Digital input to capture binary events like a door open/close switch, part-present signal, or cycle complete

- Rotational encoder signals for tracking speed, revolutions, or machine movements

- Dedicated PlantStar data-collection module

With this wide range of connection options, PlantStar can monitor nearly any machine or process, regardless of age or control system.

Make Data-Driven Decisions That Dial In Your Processes

Once connected, PlantStar continuously records process data and displays it in user-friendly reports and dashboards. With this visibility, you can:

- See process data in real time

- View statistical process control (SPC) charts& spreadsheets to identify trends, variation, or drift over time

- Review historical data from any part or batch

- Compare actual data to standard profiles

- Generate reports for audits, quality control, or management review.

Improve Manufacturing Performance

By tracking process variables automatically, you catch deviations the moment they occur for fewer defects and less scrap, waste, and rework. When something does go wrong, you have the data you need to pinpoint the problem without guesswork, so you can get production back on track quickly with minimal downtime. As you build historical data, SPC provides keen insight into patterns and trends so you can always home in on the next opportunity for improvement.

Build Reliable Processes

Process monitoring provides the insight needed to build consistent, controlled manufacturing processes. As processes become more consistent, interruptions and defects will become rarer, output more stable, and both quality and efficiency will rise. The natural results are greater profitability and customer satisfaction.

Partner with an Industry Expert

With several decades of experience helping manufacturers improve operations with data-based insights, PlantStar delivers reliable performance you can trust. With installation assistance, training services, and 24/7 support, the team at will help you get the most out of your MES.

Learn more about the benefits of robust MES software!

Is your manufacturing operation falling behind schedule or struggling with excessive downtime or waste? Learn more about how a robust manufacturing execution system (MES) combines production and process monitoring to help you improve productivity and efficiency while protecting product quality. Download the complimentary ebook: How Production and Process Monitoring Can Streamline Your Manufacturing Process

Want a firsthand look at how PlantStar works?

Contact us today to schedule a demo!