Real-Time Insights for Smarter Manufacturing

In manufacturing, every second counts. Production monitoring is the cornerstone of ensuring that your operations run smoothly, efficiently, and with minimal waste. By capturing and analyzing production data in real time, manufacturers gain unparalleled visibility into machine performance, job progress, overall efficiency, and a huge impact in labor savings.

PlantStar’s Manufacturing Execution System (MES) goes beyond basic monitoring. It provides a comprehensive platform to track key production metrics such as cycle time, output rates, and scrap percentages while integrating seamlessly with your existing ERP systems. With PlantStar’s production monitoring capabilities, you can transform your shop floor into a data-driven powerhouse, reducing costs and optimizing output.

Why Production Monitoring Matters

Understanding what’s happening on your production floor in real time is critical for staying ahead in today’s manufacturing environment. Production monitoring provides that visibility. More than just letting you know how many parts are coming off the line in a given length of time, production monitoring can gather, organize, and clearly present the data you need to assess performance, identify inefficiencies, and make evidence-based decisions to improve throughput, reduce waste, and raise product quality.

Production monitoring allows supervisors to see critical production data at a glance so they can act on it quickly. They may notice, for example, that a particular line is running below its expected rate or that frequent short stops are related to material changeovers or operator delays. Instead of discovering these issues at the end of the shift or in the next day’s report, they can respond immediately to keep production on track.

Tracking production in real time provides the data needed to answer questions like:

- Are we meeting our daily production targets?

- Have there been changes in output, downtime, or work-in-progress inventory?

- Is a particular machine underperforming or contributing to downtime?

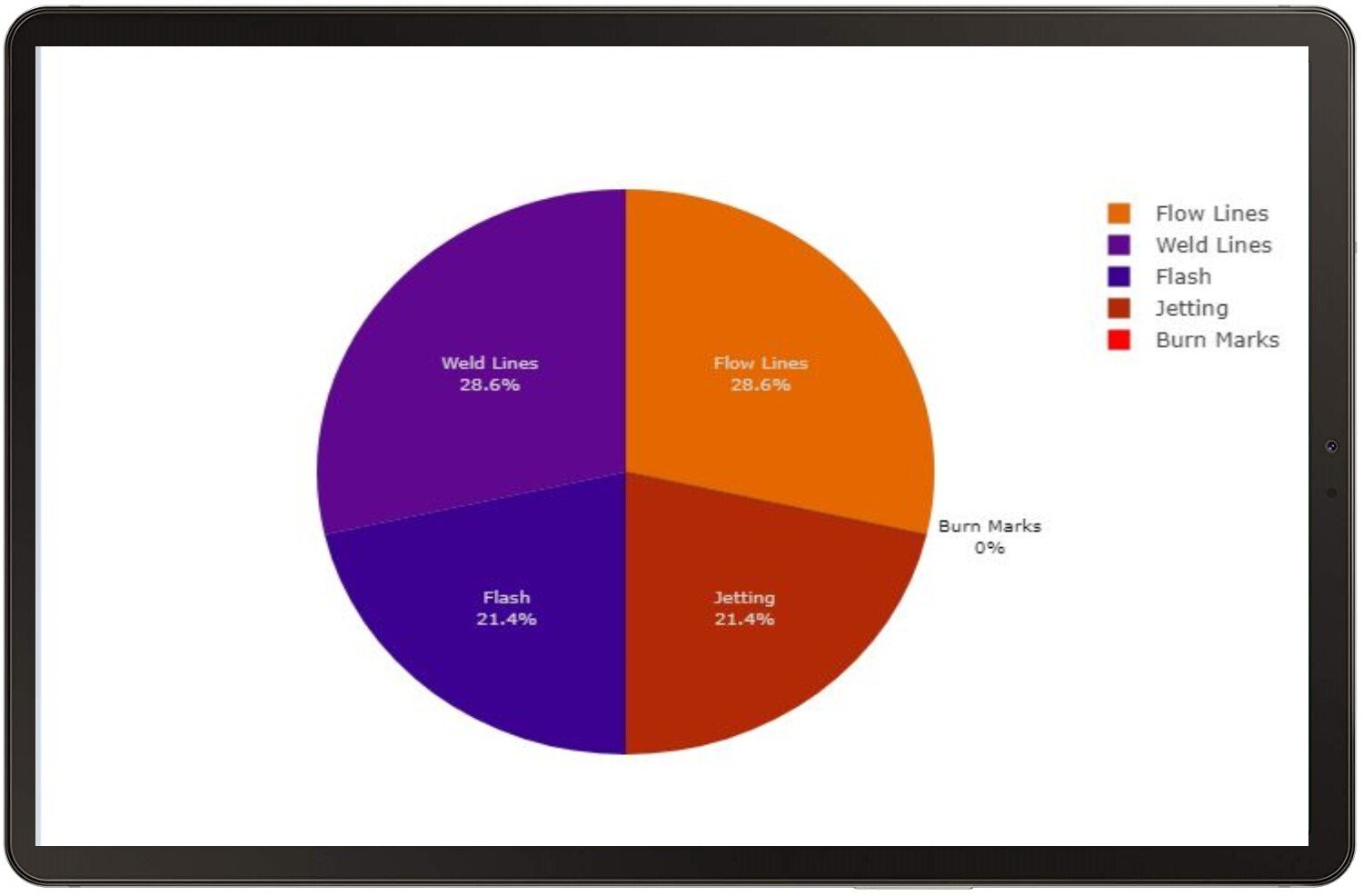

- Is scrap or rework creeping in, and can we catch the problem earlier in the process?

Unlike process monitoring, which focuses on how products are made, production monitoring tracks how many are made in a specified period of time. It allows you to track not only total output but also machine status, operator performance, and overall equipment effectiveness (OEE). This is a powerful tool for achieving quick wins like boosting uptime and output.

PlantStar’s production monitoring helps you turn those questions into actionable insight.

Production Monitoring with PlantStar

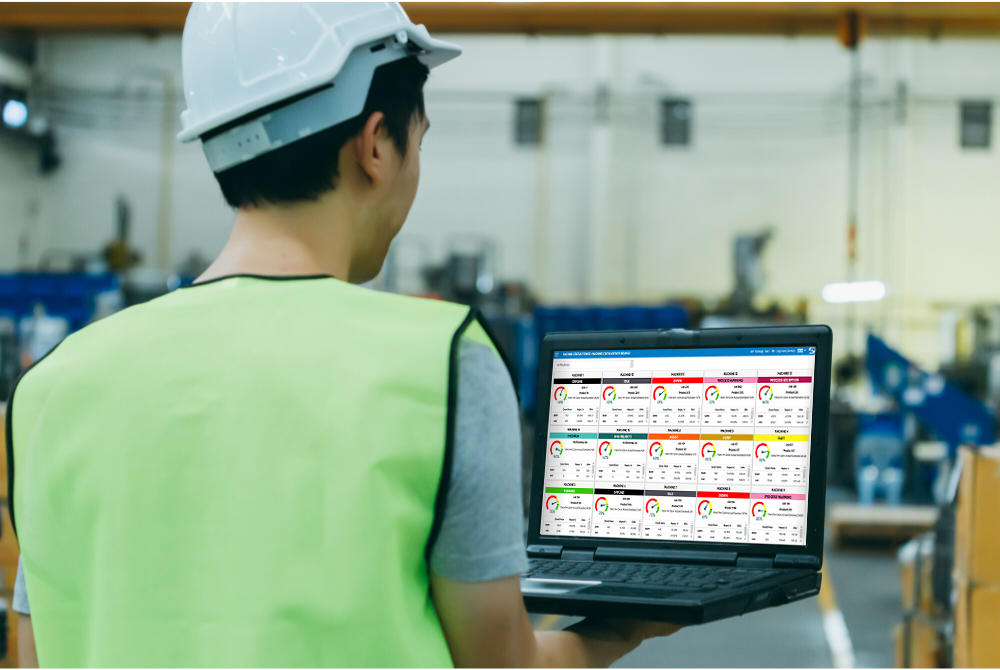

PlantStar captures production activity in real time, so your team always has a live picture of what’s happening on the shop floor.

- Track production as it happens, either by rate or part count.

- Continuously track and record the complete history of machine uptime and downtime to spot bottlenecks or unexpected halts in production.

- View OEE in real time.

- Display all data in configurable reports and dashboards, so your team is continuously getting the information that matters most.

- Set events such as production slowdowns or unexpected downtime to trigger instant email, text, or text-to-voice alerts.

- Integrate with enterprise resource planning (ERP) as well as peripherals like scales, visual inspection systems, barcode scanners, and label printers for a complete, end-to-end view of production.

- Use optional RFID or fingerprint login for visibility into who is running each machine at any given time, and easily identify performance variations and training needs.

- Upload documents like product standards and job instructions, so operators always have the up-to-date information they need at their fingertips.

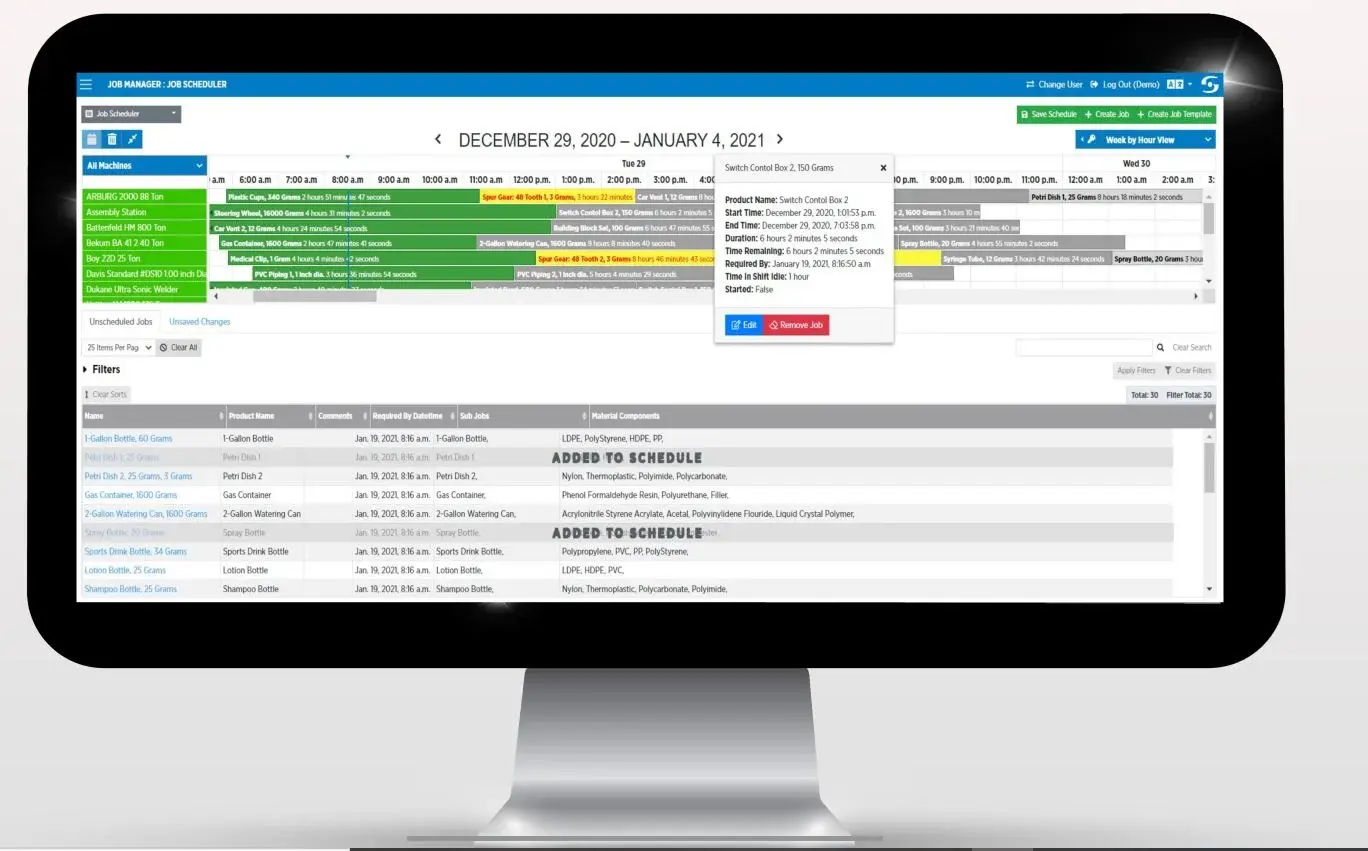

Make Faster, Better Production Decisions

The days of waiting for end-of-shift reports to see how a production run went are over. Real-time visibility into key data enables faster and smarter responses to any disruption in production flow. Instant alerts ensure your team is immediately alerted to any issues, so they can correct them as quickly as possible to reduce scrap and waste, limit downtime, and keep production on schedule.

Data analysis and reporting empowers you to make fact-based decisions, eliminating the need for time-consuming manual logs or guesswork. By identifying patterns in variables like production rates, downtime, scrap, and operator performance, you can more easily pinpoint inefficiencies and highlight recurring issues.

Improve Manufacturing Performance

With continuous, accurate production and downtime tracking, you can optimize line schedules, balance workloads across machines, and make real-time adjustments to meet demand. As you reduce downtime, rework, and scrap and increase throughput and OEE, you can reduce costs, improve delivery performance, and boost profitability.

Avoid Surprises

Real-time production monitoring lets you build a reliable, predictable production environment. Supervisors, managers, and operators can view a consistent flow of production data, reducing surprises while enabling continuous improvement.

Partner with a Trusted Industry Expert

With several decades of experience helping manufacturers improve operations with data-based insights, PlantStar delivers reliable performance you can trust. With installation assistance, training services, and 24/7 support, the team at PlantStar will help you get the most out of your MES.

Learn more about the benefits of robust MES software!

Is your manufacturing operation falling behind schedule or struggling with excessive downtime or waste? Learn more about how a robust manufacturing execution system (MES) combines production and process monitoring to help you improve productivity and efficiency while protecting product quality. Download the complimentary ebook: How Production and Process Monitoring Can Streamline Your Manufacturing Process

Want a firsthand look at how PlantStar works?

Contact us today to schedule a demo!